Application

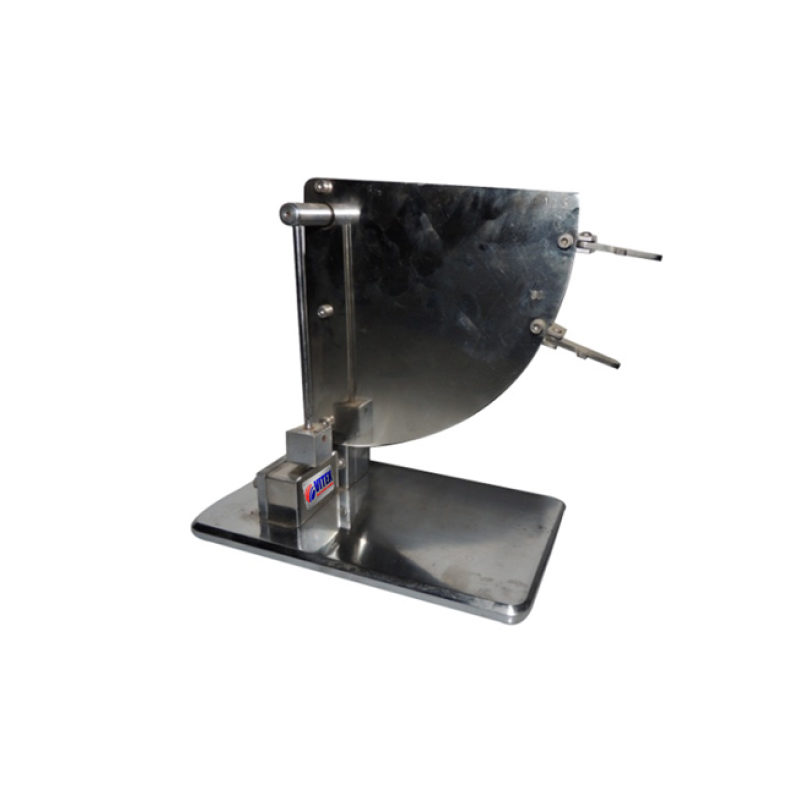

Izod-type Impact Machine, to determine all types of buttons (10mm diameter and over) to encounter violent blows during clothing manufacture or use, by a pendulum of a specified mass released from a specified height to strike the button. Observe and record if the button breaks, fractures, or distorts.

Standards

BS 4162, GB/T 22704

Weight

25 Kg

Dimensions

260 x 260 x 300mm (L x W x H)