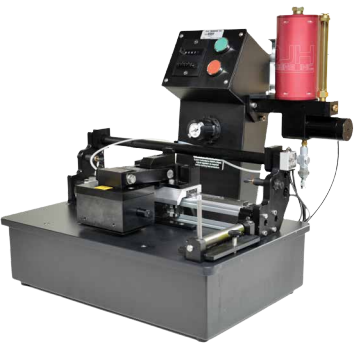

MEK Rub Test Machine

The MEK Rub Test machine has been developed to combat the problem of inconsistent test results between operators. This semi automated machine gives the line operator and quality control personnel the ability to duplicate results from the laboratory to the production line every time. The front panel mounted controls make it simple for the user to program therequired number strokes to run for a specified test, then simply lower the head, close the cover, and press the start button, the machine will do the rest. This frees the operator to perform other QC test while the machine performs the rub test consistently and reliably with the added benefit of greatly reducing operator contact with and exposure to the solvents being used for the rub test procedure. Once the cycle counter reaches the preset number of strokes the unit will shut off the solvent flow and return to the start position ending the test.The operator can return at any time to check the results of the Rub Test. The quick change solvent pad system means that preparing for the next test procedure is quick and efficient.

Features and Benefits

- Easy to setup, simple to operate

- Repeatable consistent results, constant pressure dead weight rubbing block

- Front panel mounted controls

- Minimal solvent usage, adjustable solvent flow metering valve

- 425cc solvent reservoir with auto shutoff control

- Quick Change solvent pad system

- Controlled Stroke count, counter can be set from 1 to 9999 strokes

- CE Certified

- Intrinsically safe – no electrics, all pneumatic operation.

- Minimized operator contact with

and exposure to Solvent

Optional Accessories

Variable Stroke Kit

This add on kit allows for the use of non standard

size panels. Panels ranging in length from 85mm

(3.5”) to 305mm (12”)