Application

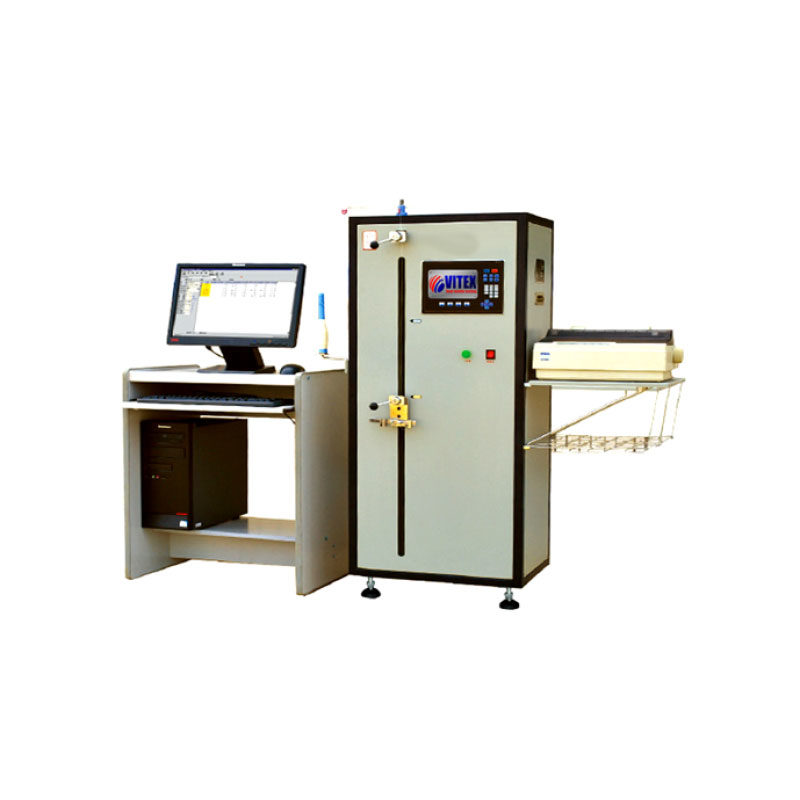

Automatic Single Yarn Strength Tester, to determine the breaking strength and elongation rate of single yarn made of cotton, wool and others up to 6000cN, with air-driven clamps. Fully automatically test up to 20 cops at the same time.

Features

- Working pattern is CRE principle, controlled by software running in computer

- Automatic feeding of yarn, and automatic clamping for test, fast and without damages to yarn

- Fitted with Waste yarn collecting device, to make labs clean

- Test up to 20 cops at the same time

- Software is offered thus the machine can be controlled by a computer. The built-in printer or an additional printer can print test reports.

Standards

ASTM D2256, ISO2062, GB/T398, GB5324, GB/T14344, BS, JIS, AS, CAN/CGSB

Power / Air

220V 50 Hz 0.4 ~ 0.8mPa

Weight

140 Kg

Dimensions

550 x 450 x 1600 mm (L x W x H)