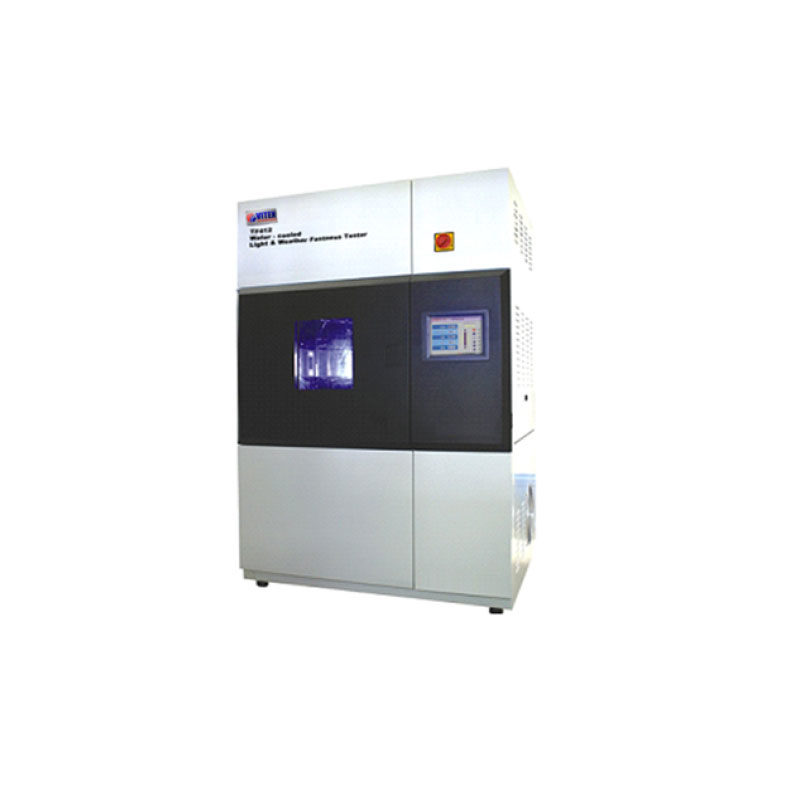

Application

Water-cooled Light & Weather Fastness Tester (Weatherometer), to determine the color fastness, aging resistance of textiles, plastics, rubber products or materials by objecting to the simulated conditions of nature weather (daylight, rain, temperature and humidity, etc.). The tester simulates both light and dark cycles and nature weather conditions by rack sprays and water-cooled long-arc-xenon lamp equipped.

Features

- Light intensity set digitally, real-time monitoring, automatically adjust to meet the different standards required for testing the stability of light source (optional 420nm or 300 ~ 400nm band monitoring)

- Blackboard Thermometer (BPT), the Standard Blackboard Thermometer (BST), Irradiance detector and samples placed in the same position, a true reflection of the sample under test conditions, the data displayed as figures, charts, curves on the large color screen, no need to stop for observation.

- Large colorful display, a variety of test monitoring modes (animation, digital, graphics) operate easily and clearly.

- Sample holders can be timed independently to achieve different tests simultaneity in the

same machine - Equipped with Water-cooled rated 4500W long-arc-xenon- lamp, truly simulates the daylight spectrum.

- Professional water circulation system, reduce operating costs.

- Industrial temperature control (cooling) system offers quickly and smoothly control

- Ultrasonic humidifier, professional dehumidification system to ensure accurate and stable

humidity conditions. - Equipped with self-circulation system and air filtration system, significantly reducing the

environmental requirements. - Cooled by circulating water chillers / water cooling two options to choose from.

- Quality assurance of 1000 hours continuous running.

- Front and back sides spray pattern on samples.

Standards

AATCC 16, AATCC 169, ISO105-B02/B04/06, ISO4892, ASTM G155, GB/T 8427, GB/T 8430, GB/T 14576, GB/T 1865, GB/T 1766, GB/T 15102, GB/T 15104, GB/T 16422.1, GMW 3414, SAEJ 1960, SAEJ 1885, JASO M346, PV 1303, M & S C9, JIS L0843

Power

380 V 50 Hz 12 KW

Weight

300 Kg

Dimensions

1000 x 800 x 1800 mm (L x W x H)