Application

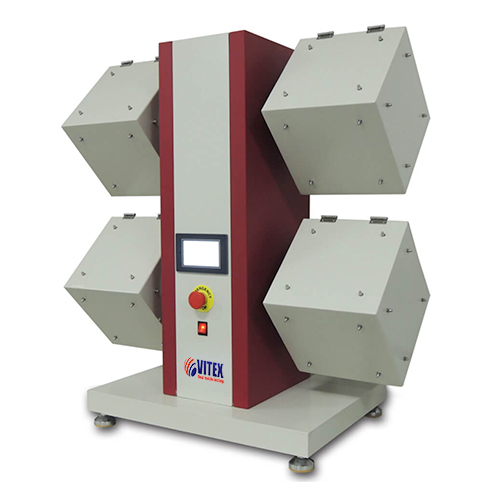

ICI Pilling Tester / Pilling Box. To rapidly replicate pilling on fabrics in a fraction of the time due

to normal wear.

ICI pilling tester uses a universal drive system with 2 or 4 position, electronic digital counter,

and sample mounting fixture. The machine accepts ICI Pilling boxes and ICI pilling drums.

Optional Accessories

- Pilling Assessment Viewer

- Set of 5 Photographic Standards

- Mounting Jig (used to install specimens easily)

- Cork liner – pack of 6

- Rubber tube – pack of 4

Optional Standard

- SnagPod for BS 8479

- Snagging pins for JIS L1058

Standards

ISO12945-1, BS 5811, NEXT 19, IWSTM152, M&S P18, P19, P21A,

Power

220 /110 V 50/60 Hz

Weight

125 Kg

Dimensions

800 x 500 x 600 mm (L x W x H)