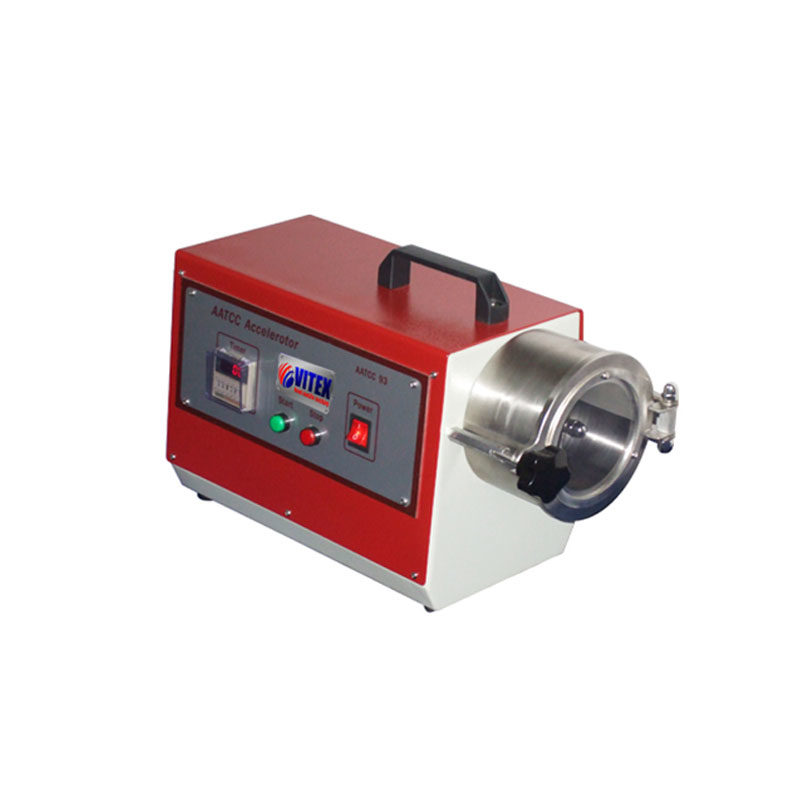

Application

AATCC Accelerotor, to rapidly determine abrasion resistance of flexible materials including textiles, paper, leather and plastics in both wet and dry conditions. Samples are rapidly tumbled within a cylindrical test chamber lined with an appropriate abrasion material. The tumbling action is provided by a propeller shaped rotor for a predetermined time at a predetermined speed, wet and dry.

The abrasion resistance is evaluated by determining the weight loss of the specimen or grabbing strength loss of the specimen when broken at an abraded fold line.

Standards

AATCC 93, M&S P26 / P53, NEXT31

Power

220 /110 V 50/60 Hz 3A

Weight

26 Kg

Dimensions

480 x 220 x 320mm (L x W x H)