Universal Testing Machine

Universal Testing Machine is a versatile and highly reliable equipment that is widely used to test the mechanical properties of various materials, components, and structures. UTM is design to perform a wide range of tests including tension, compression, bending, flexure, shear, and fatigue testing. In this article, we will discuss the types, parts, and applications of Universal Testing Machine.

There are two main types of Universal Testing Machine , electromechanical and hydraulic, and the main components of UTM include the load cell, grips, crosshead, control panel, and software. Universal Testing Machine is widely used in various industries to test the mechanical properties of materials and is an essential tool for quality control and product development.

Types of Universal Testing Machine

There are two main types of UTM, electromechanical and hydraulic. Electromechanical UTM is powered by an electric motor and is used for testing smaller samples, while hydraulic UTM is powered by hydraulic fluid and is used for testing larger and stronger materials.

Parts of Universal Testing Machine

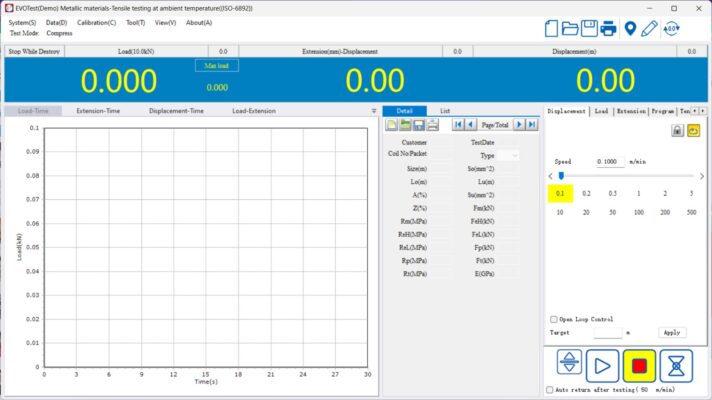

The main components of UTM include the load cell, grips, crosshead, control panel, and software. The load cell is responsible for measuring the force applied to the sample during the test. The grips hold the sample in place and transmit the force from the machine to the sample. The crosshead moves up and down to apply force to the sample. The control panel is use to set up the test parameters and monitor the test progress. The software is use to collect and analyze the test data.

Applications of Universal Testing Machine

UTM is widely used in various industries such as automotive, aerospace, construction, and biomedical to test the mechanical properties of materials, components, and structures. Some of the common applications of UTM include testing the tensile strength, compression strength, bending strength, flexural strength, shear strength, and fatigue strength of materials. UTM is also used to test the hardness, fracture toughness, and impact resistance of materials.

More : https://www.aimil.com/blog/what-is-universal-testing-machine/

Components of Universal Testing Machine

A universal testing machine is constructed of two main parts:

1. Loading Unit

The loading unit stores the test specimen configuration as well as the load exertion.

The loading unit of a UTM consists of the following components :

1 Load Frame

2 Upper crosshead and Lower crosshead

3 Elongation Scale

Load Frame

A universal testing machine’s load frame can be designed with a single or double support. The load Frame is made composed of a table (on which the specimen is put for compression testing), an upper crosshead, and a lower crosshead.

Upper crosshead and Lower crosshead

One end of the test specimen is clamped using the top crosshead. The lower crosshead in the load frame is the moveable crosshead, with screws that may be released and tightened for height adjustment. The crossheads both feature a tapering slit in the centre. This slot is equipped with a pair of racking jaws designed to grasp and hold the tensile test specimen.

Elongation Scale

An elongation scale included with the loading unit measures the relative movement of the lower and upper tables

2. Control Unit

The control unit obtains the changes in load application and the accompanying test result.

The following are the major components of a universal testing machine’s control unit:

1. Hydraulic Power Unit

2. Load Measuring Unit

3 .Control Devices

Hydraulic Power Unit

This unit consists of an oil pump that delivers non-pulsating oil to the load unit’s main cylinder. This flow facilitates the application of load to the specimen. An electric motor and sump operate the oil pump in a hydraulic power unit.

Load Measuring Unit

This unit has a pendulum dynamometer with a tiny cylinder containing a piston that moves with the non-pulsating oil flow. The pivot lever connects the pendulum to the piston. The load on the specimen causes the pivot lever to deflect. This deflection is transformed into a load pointer and shown on the dial as the load.

Control Devices

Control devices can be either electric or hydraulic. Electric control devices employ switches to adjust the crossheads and turn the machine on and off. A hydraulic control device is made up of two valves: the right control valve and the left control valve, also known as the release valve. To impart load to the specimen, a proper control valve is used.

Functions of Universal Testing Machine

UTM’s primary duties are to test the mechanical characteristics of materials. UTM’s standard tests are as follows:

1. Tensile Test

2. Compression Test

3. Adhesion Tests

4. Pull-Out Tests

5. Bending Test

6 .Hysteresis Test

Concrete, steel, cables, springs, steel wires and chains, slings, links, rope, winches, steel ropes, and other materials may all be tested using UTM.

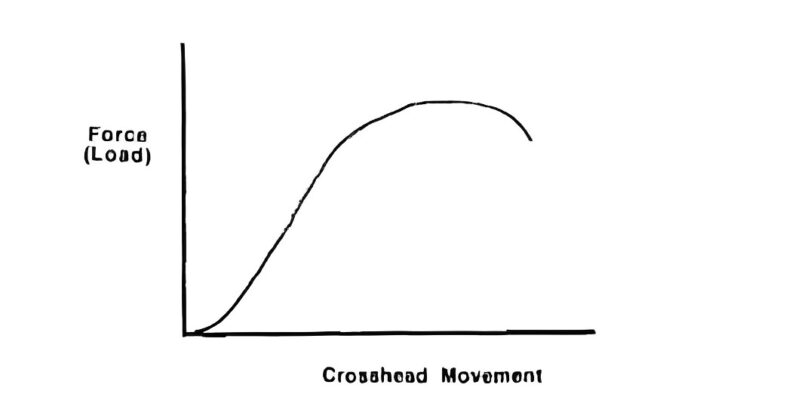

Universal Testing Machine offers the load application value as well as the corresponding displacements. The load deflection graph is derived from the observed value. The load value is shown on the Y-axis, while the displacement is shown on the X-axis. The displacement is caused by the movement of the crossheads during the application of the load

The stress-strain analysis, modulus of elasticity, and yield strength of the specimen examined may be calculate using the load deflection graph.

Check out our other blogs:

1.ISO 1924-2 Tensile Tests Of Paper and Board

2.ISO 6892-1 Metallic Materials Tensile Testing

3.ASTM D5035 Breaking Strength and Elongation of Textile Fabrics