International Organization for Standardization (ISO) is an independent, non-governmental, and international organization that develops standards to ensure the quality, safety, and efficiency of products, services, and systems. The purpose of the ISO standard is to designed to make products and services better and to make companies, governments, and other organizations more efficient. ISO 6892 is designed for specific industries, like the food industry, or designed to help improve the environment.

ISO 6892-1 Metallic Material Tensile Test

Description For ISO 6892 -1

One of the most often used test standards for the tensile testing of metallic materials at room temperature is ISO 6892-1. In the most recent version of this standard three separate test methods—Method A1, Method A2, and Method B are covered, which was published in 2016. ASTM E8/E8M and ISO 6892-1 are related but not identical.

ISO 6892 is divided into 4 different parts and each of which addresses one of the above-mentioned temperature ranges:

- ISO 6892-1 test method at room temperature

- ISO 6892-2 test method at elevated temperature

- ISO 6892-3 test method at low temperatures

- ISO 6892-4 test method in liquid helium

Specimens For ISO 6892 -1

Due to the enormous variety of uses for metallic materials, ISO 6892-1 may accept a wide range of specimen types and The Type contains comprehensive information on specimen preparation and measurement:

Type 1: Type of test pieces to be use for thin products: sheets, strips, and flats between 0, 1, and 3 mm thick.

Type 2: Type of test pieces to be use for wire, bars, and sections with a diameter or thickness of less than 4 mm.

Type 3: Type of test pieces to be use for sheets and flats of thickness equal to or greater than 3 mm and wire, bars, and sections of diameter or thickness equal to or greater than 4 mm.

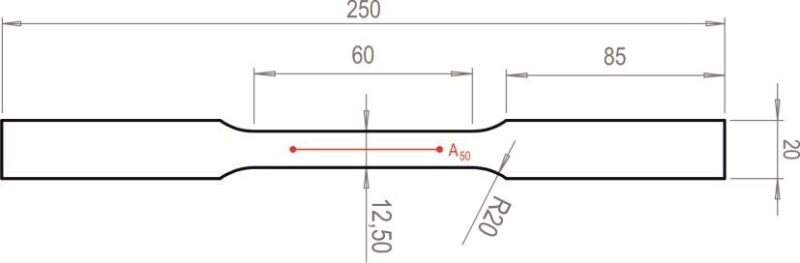

Specimen Dimension For ISO 6892-1

What Does ISO 6892 Measure?

ISO 6892-1 most frequently measures the following:

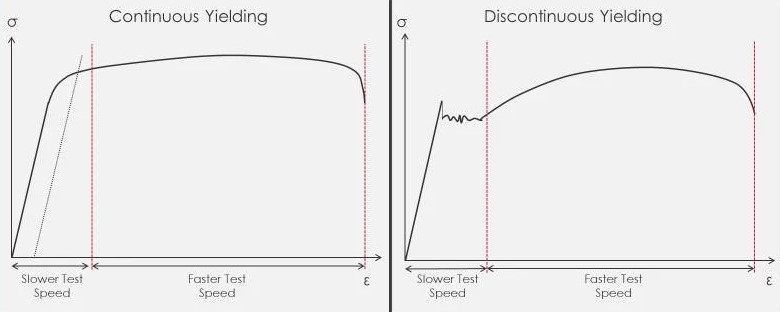

- Yield Strength – The amount of strain at which a material will distort permanently. Besides, ISO 6892-1 specifies the upper and lower yield strength criteria for discontinuously yielding materials.

- Yield Point Elongation – Which is only appropriate for discontinuously yielding material and it is the difference between the specimen’s elongation at the beginning and end of the yielding process.

- Tensile Strength – During a tensile test, a material can withstand maximum force or stress.

- Reduction of Area – An evaluation of a material’s ductility, and this is the difference between the area of a specimen’s original cross-section and the area of its smallest cross-section after testing.

Metal Yield Types

Grips For ISO 6892 -1

Grip and jig selection is important to obtain accurate results and specimen alignment is key to avoiding side loading or bending moment.

1. Mechanical wedge grip 2. Tensile wedge grip 3. Jaw tension clamp

These mechanical grips are designed to self-tighten during the tensile test progresses. Suitable for flat and round specimens for high-strength tensile testing. Wedge grips are a popular tensile testing tool for metallic materials.

Extensometers

When performing a Tensile test on metallic materials, we need a high-accuracy device to measure the material’s deformation and a slightly lower-accuracy device for high-strain values such as uniform elongation or total elongation.

The extensometer shown below can be used to perform tensile tests on metallic materials.

1. Electronic extensometer

Type of UTM machine

We recommend using UTM machines with a capacity of 50kN- 100kN however it depends on the strength of the materials. Next, We also recommend using a dual-column floor-type machine.

The VEW 2302 Computer Servo Type Universal Testing Machine is a new material testing machine that combines electronic technology and mechanical transmission.

Besides, We need accurate load speed, range of force measurement, high accuracy and sensitivity for load, displacement measurement, and control. It can also test constant-velocity loading and constant-velocity displacement.

We recommend using this machine because it’s simple to operate and is especially suitable for controlling quality in the production line.

Testing Software For ISO 6892-1

The software that comes pre-installed on almost all modern testing equipment must be in line with ISO 6892-1 and match the data that is already available and you select must deliver accurate results because not all software packages are made equal.

Test Procedure For ISO 6892-1

- Prepare the specimens as described in the method.

- Place the specimen into grips.

- Clamp the specimen at the top of the grip first then carefully clamp the sample into the bottom grip.

- Attach the extensometer to the specimen

- Zero all the testing machines before starting the test

- Begin the test by Click start button on the software

- End the test after the sample break

There are different styles of grips available for different brands of equipment but the concept is the same.