ASTM is an international standards organization that is located in the United States of America. The purpose it was introduced to the industries is to publish technical standard agreements for various materials, product, systems and others. Among the ASTM standards that are often use in the industries is ASTM D695.

ASTM D695 Test Standard

Description For ASTM D695

ASTM D695 is an international test standard designed to determine the compressive properties of un-reinforced and reinforced plastics. The purpose of this test is to provide information about the compressive properties of plastics when employed under conditions approximating those under which the tests are made. Manufacturing industries such as polymers often use this standard. Nowadays, ASTM standards are highly preferred by both corporate or government bodies. In Malaysia, most industries use the ASTM D695 standard in their companies. The Malaysian government has also adopt this standard.

Basically, ASTM D695 measures the compressive properties the behavior of a material when it is subject to a compressive load. Loading is at a relatively low and uniform rate , Compressive strength and modulus are two common values generate by the test. This test can be perform on using Universal Testing Machine (UTM). The following are the properties measure through the ASTM D695:

- This test is measure the determining the modulus of elasticity, yield stress, deformation beyond the yield point, and compressive strength

Specimens For ASTM D695

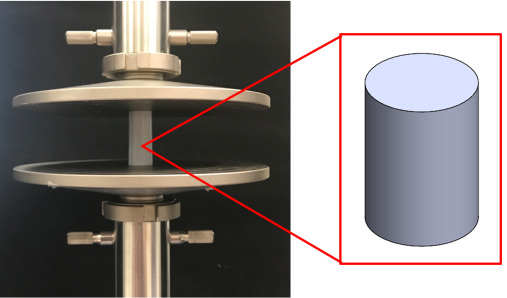

For ASTM D695, the specimens can either be blocks or cylinders. This type of specimen is of course made of plastic. For ASTM, the typical blocks are 12.7 x 12.7 x 25.4mm. and the cylinders are 12.7mm in diameter and 25.4mm long.

Grips For ASTM D695

1. Compression platen grip

To perform this test, the compression tool use must be flat. This is because uneven surfaces will interfere with the test results.

- For hard materials such as steel, plastics, stone etc.

- Hardened steel 58 HRC, black phosphate coating

- Temperature range: 0°C – +350°C

- Nickel plated: -70°C – +350°C

- Max capacity depends on the size of the coupling

- The size of the compression platen is 5cm to 20cm.

Extensometers For ASTM D695

To obtain accurate force data, ASTM D695 also requires an extensometer to measure compressive strain. But the extensometer used for this test is different from that use on the tensile test.

Type of UTM machine

We recommend using UTM machines that have dual column design such as VEW 2308 and VEW 2302. For machine specification, it depends on the maximum expected forces.

1. VEW 2308

The machine is design by mechanical-electrical integration, the composition of the force-measuring Sensor, transmitter, microprocessor, mechanism of load drive, computer and color inkjet printer. The high-precision electronic motor can be set to five-speed, the components are connect by plug-way, Floor-standing models, it is taken account of modern industrial design and ergonomics in modelling and Coating. It can be tested with all the materials in the stretch, compression, bending, shear, embedded relay, Peeling. tearing, crack, etc, such as rubber, plastics, leather, metal, nylon wire, fabric, paper, aerospace, packaging, construction, petrochemical, electrical, vehicle, etc.

The implementation of standards and standard configuration:

- GB/T4689.20-1996 Measuring fastness of leather’s adhesion

- QB/T2710-2005 Measuring leather’s expansion and the rate of elongation

- QB/T2711-2005 measuring tear force of leather

- QB/T2712-2005 measuring leather’s strength and stretch of spherical crack test

2. VEW 2302 Series

VEW 2302 Computer Servo Type Universal Testing Machine is a new material testing machine that combine with the electronic technology and mechanical transmission, it has accurate load speed, range of force measurement, has high accuracy and sensitivity for the load, displacement measurement and control, it also can be tested the constant-velocity loading, constant- velocity displacement.

This machine is simple to operate, especially suitable for controlling quality in production line, this series of machine is mainly apply to test the non-metallic and metallic materials which the load is less than 30ton.

Main Function:

- Mainly apply to test the metallic and non-metallic materials in tension, compression, bending, shear, peel, tear or two-points extensions and others.

- Can be used for materials such as rubber, plastic, wire and cable and optical fiber and cable, safe belt, leather belt composite materials, plastic profiles, waterproof membrane, steel, copper, profiles, spring steel, bearing steel, stainless steel (as well as other high-hardness steel), castings, plate, strip, non-ferrous metal wire.

Test Procedure

- Place the specimen between the compressive plates and make sure it parallel to the surface.

- Align the specimen until it is exactly in the center of the compression plates.

- Adjust the crosshead until it makes contact with the compression fixture.

- Use an extensometer if stress-strain or design is desired.

- Then compress the specimen at a uniform rate until failure.