ASTM is an international standards organization that is located in the United States of America. The purpose it was introduced to the industry is to publish technical standard agreements for various materials, product, systems and others. Among the ASTM standards that are often use in the industry is ASTM D6319.

ASTM D6319 Test Standard

Description For ASTM D6319

ASTM D6319 is an international test standard used by the biomedical industry to testing the tensile properties of medical gloves. This test standard covers certain requirements for nitrile rubber gloves used in medical applications. Other than that, it also determines the tensile strength and the ultimate elongation of medical glove samples.

Manufacturing industries such as biomedical often use this standard. ASTM D6319 is commonly use during the quality control process. The main reason it is use is to ensure that the gloves produce to meet the expected criteria for tensile strength and elongation. This is to prevent gloves do not fail during use. Meeting the set standards is very important because glove failure in medical settings could expose the care provider or patient to dangerous and potentially life-threatening contaminants.

Nowadays, ASTM standards are highly preferred by both corporate or government bodies. In Malaysia, most biomedical industry uses the ASTM D6319 standard in their companies. The Malaysian government has also adopted this standard. Tensile tests can be perform on using Universal Testing Machine (UTM) and also known as a tensile testing machine. The following are the properties of tensile commonly measured through ASTM D6319:

- Tensile strength

- Elongation

Specimens For ASTM D6319

The specimen must be die-cut according to specifications as found in the standards. To cut the shape of the specimen, ideally using a die cutter. The shape of the specimen is design to create tension when the specimen is pulled.

1. Dumbbell or dogbone cutter

- Dogbone specimens must be die cut using special equipment known as dumbbell cutters. The dumbbell cutters need to be calibrated using a VMS machine so that the size is more accurate.

2. Medical glove specimen (Dogbone)

- Standards prescribe dumbbell-shaped specimens cut from the glove

ASTM D6319 require two types of specimens:

a) Directly from the manufacturing line

b) After undergoing accelerated aging

Grips For ASTM D6319

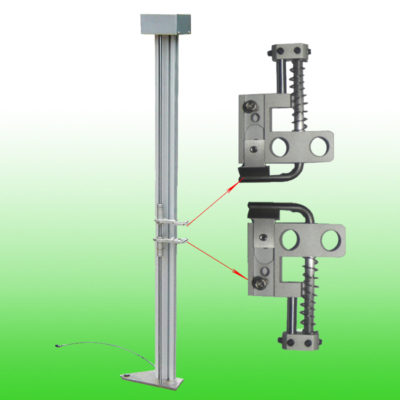

1. Eccentric Roller Grip

Easy to use and self-tightening applicable for soft and flexible samples, foils, plastics, rubber, etc.

2. Pneumatic Grip

Pneumatic grips are particularly useful when a variety of materials. The gripping force is generate by pneumatic cylinders acting directly on the jaws or via a lever system.

Extensometers For ASTM D6319

- Long-travel contact extensometer design to measure displacement in tensile tests of soft material with considerable elongation.

- The Long-Travel extensometer can also be use through specimen break.

- The extensometer is not required by the standard but needed for the most accurate and repeatable results.

- We recommend the users to use the extensometer because to get good and accurate results. Elongation is an important design characteristic of rubbers and elastomers so an extensometer need be used to improve the accuracy of the measurement.

Type of UTM machine

We recommend to use UTM machines with a capacity of 50N-2kN, it depends on the strength of the specimen. We also recommend to use smaller machines such as single column or dual column floor types. Due to the low forces involved, a 500 N load cell is consider the maximum when testing to these standards.

1. VEW 220E

VEW 220E desktop computer servo testing machine is a new material testing machine that combined with the electronic technology and mechanical transmission, it has accurate load speed, range of force measurement, Has high accuracy and sensitivity for the load, displacement measurement and control. This series of machine using single-space structure, operational space at the bottom, it is mainly apply to test non-metallic and metallic material, which the load is less than 1kN, it has the parameters, such as stress, strain, the control mode of displacement, calculated max force, tensile strength, bending strength, compressive strength, elastic modulus, rate of elongation, yield strength and others.

Main function:

This machine can be apply to test lots of materials in tension, compression, tear, peel (can 90 degrees and 180 degrees) and other mechanical tests, such as rubber, tires, belt, shoes, plastic, film, acrylic, FRP, ABS, EVA, PU, aluminium-plastic pipe, composite materials, waterproof materials, fibers, textiles, wire and cable, paper, gold foil, ribbons, thread, spring, wood, medicine packaging materials, tapes etc.

2. VEW 2307

VEW 2307 Desktop microcomputer-type tensile testing machine is designed by our company which is made of aluminium, it is not only small, used widely, do not take up space, nice appearance, but also easy to move with the hoop, it is very convenient to operate.

- It is controlled by computer and printing out the testing report; the outward appearance used the closing board dealing with high-level baking varnish, which obviously elegant

- It especially suitable for controlling quality in the production line, this series of machine is mainly applied to test the non-metallic and metallic materials which the load is less than 2KN

Test Procedure

- Prepare the specimens as described in the method.

- The specimen is die-cut to the appropriate shape (dumbbell/dogbone) from a glove.

- Place the specimen into grips.

- Clamp specimen at the top of the grip first then carefully clamp the sample into the bottom grip.

- Attach the extensometer to the specimen

- Zero all the testing machine before starting the test.

- Begin the test by Click start button on the software.

- End the test after sample break (rupture).

Check Out Our Other Blogs:

1.ASTM D2256 Test Standard

2.ASTM A938 Test Standard

3.ISO 6892-1 Metallic Materials Tensile Testing