Computer Control Electromechanical Universal Testing Machine

VAW 8000D Computer Control Servo Hydraulic Universal Testing machine is guaranteed to meet ISO15579-2000, ISO679, ISO7438-1985, ISO6892, EN100021-1-2001, ASTM E8M, JIS Z2241-1998, ISO75000-1, ISO4012, ISO10065 and other international and national specifications, which are suitable for tension, compression, bending, shear and other tests by adding different test fixture for metal and non-metal materials. It adopts hydraulic power pack to drive the piston in the oil cylinder to provide testing load. By using load cell and photoelectric encoder, the computer is timely showing the testing parameters like testing load, piston stroke, deformation of specimen and various kinds of testing curves etc. This machine is servo control mode and the computer with strong function software does data processing and issues the test reports. The software based on Windows system is able to make automatic calculating of test results, i.e. tensile strength; upper / lower yield strength, Non proportional stress point etc. Report creation function makes it is very simple to make testing report in needed format. It is necessary inspect device in the filed of steel and iron factory, the laboratories of scientific research institutes, infrastructure construction organs, machinery plants and education for research and teaching , etc.

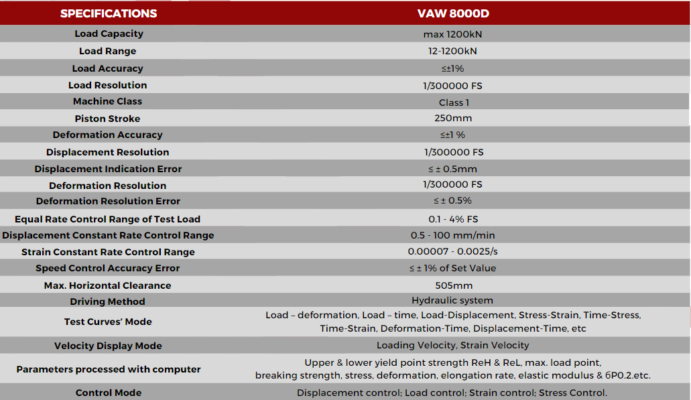

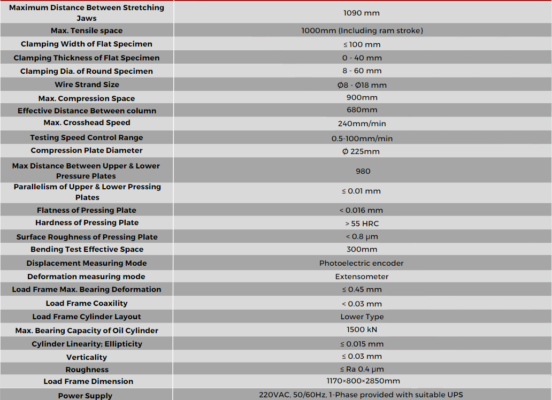

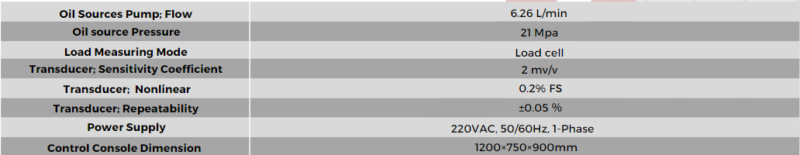

GENERAL SPECIFICATIONS

- Force Application within range of the testing machine

- Load shall be transmitted axially

- Gripping of the reduced section specimen restricted to the grip section

- Speed of testing not greater than that at which load and strain readings can be made accurately

- Speed of testing expressed in terms of free running crosshead speed, separation of the two heads, rate of stressing the specimen, or rate of straining the specimen.

- The machine must be complete with attachments/accessories and different size of grippers needed for tensile, flexural, compression and other testing that it is capable of.

SAFETY FEATURES

The system includes the following safety features

- Emergency stop switch

- Overload limit

- Ram-Stroke limit

- Hydraulic pump motor over-current and overheating protection

- Leak / Over-current protection

- Automatic stop control

- Safety Guard

OTHER FEATURES

- Over size prestressed 4 column with twin screw

- High toughness fragment safety guard

- High precision loadcell RAM

- Built-in shock absorbing system on base mounting

- Console Control Unit