-

- Home

- Company

- Products

- Universal Testing Machines

- Textile Testing Machines

- Material Testing Machines

- More..

- Metallographic Sample Preperation Machines

- Paint Coating Measurement and Test Equipment

- Food and Packaging Test Machine

- Leak and Seal Strength Tester

- Heat Seal Tester

- Ink Rub Tester (Arc Type)

- Shrink Force and Ratio Tester

- Gradient Heat Seal Tester

- Ink Rub Tester (Straight Reciprocating Type)

- Coefficient of Friction Tester

- Incline plane COF tester

- Coefficient of Friction and Peeling tester

- Stretch Film Peel Cling Tester

- Falling ball impact tester

- Falling dart impact tester

- Hot Tack Tester

- Leak Tester

- Film Pendulum Impact Tester

- Film Free Shrink Tester

- Thickness tester

- Industries

- Services

- Blog

About Us

Victor Manufacturing Sdn Bhd is an associate company of Equipment Resources Sdn Bhd, recognized for its expertise and innovation in delivering top-quality technical services.

We provide a comprehensive range of solutions designed to enhance the quality, durability, and performance of your products which are all tailored to meet diverse client needs,

Backed by advanced testing capabilities and a highly skilled technical team, we deliver results that consistently exceed expectations.

We offer certified testing, fabrication, and maintenance services backed by advanced testing capabilities and a highly skilled technical team all designed to support operational excellence. Our customer-centric approach ensures that every project is executed with professionalism, integrity, and a focus on quality.

Testing Services

Mechanical Strength Testing

Packaging Testing

Melt Flow Testing

Metallographic Sample Preparation

Mechanical Strength Testing

Ensure your materials and products meet required mechanical properties through our wide

Ensure your materials and products meet required mechanical properties through our wide

range of strength testing services.

Our testing capabilities include:

• Tensile Test – Measure the maximum pulling force a material can withstand.

• Compression Test – Evaluate material behaviour under crushing loads.

• Bending Test – Assess the flexibility and strength of materials under bending stress.

• Peel Test – Determine the adhesive strength between bonded surfaces.

• Puncture Test – Test material resistance to penetration and sharp force.

• Thread & Wire Pulling Test – Validate the pull-out strength of wires and threads

Packaging Testing

Optimize packaging performance and quality with our specialized testing services:

Optimize packaging performance and quality with our specialized testing services:

• Bubble Leak Testing – Detect leaks and ensure package integrity.

• Friction Testing – Measure surface friction to evaluate material handling and stability.

• Heat Seal Testing – Analyse seal strength and ensure packaging durability.

Our advanced testing methods provide accurate data to help manufacturers improve packaging reliability and compliance with industry standards. With a focus on quality assurance, we identify potential issues early in the production process, reducing waste and enhancing efficiency. Partner with us for precise, dependable packaging evaluation tailored to your specific needs.

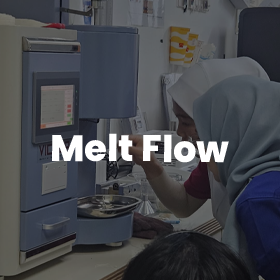

Melt Flow Testing

We provide precise melt flow index (MFI) testing to determine the flow properties of thermoplastic materials, essential for quality control in plastic production.

We provide precise melt flow index (MFI) testing to determine the flow properties of thermoplastic materials, essential for quality control in plastic production.

Our MFI testing measures the rate of extrusion of molten plastic through a standardized die under controlled temperature and pressure conditions. This data is crucial for evaluating thermoplastics.

With our advanced testing equipment and experienced technical team, we deliver accurate results that help maintain product quality and optimize production efficiency. Our commitment to precision and quality assurance makes us a trusted partner for the plastics industry.

Metallographic Sample Preparation

We support your material analysis needs with expert sample preparation, including:

We support your material analysis needs with expert sample preparation, including:

• Sample Cutting

• Sample Mounting

• Sample Grinding and Polishing

Accurate preparation ensures reliable microscopic evaluation and failure analysis. Our meticulous approach helps reveal material properties and structural details crucial for quality control and product development. Using advanced techniques and precision tools, we minimize sample distortion and preserve material integrity. Trust our experienced team to deliver consistent, high-quality results tailored to your analysis requirements.

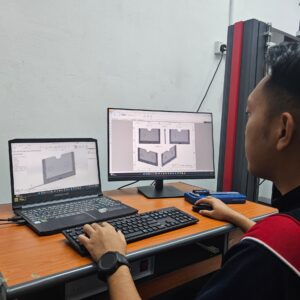

Design And Customisation

Enhance your production efficiency with our custom design and fabrication services

Calibration Services

We follow strict callibration standards to keep your equipment performing at its best

UTM Preventive Maintenance and Training Services

Keep your Universal Testing Machines (UTM) in optimal condition and ensure your team is fully prepared to operate them effectively through our training services. Our services include:

Preventive Maintenance –

Regular inspection, cleaning, lubrication, and functional

checks to prevent unexpected breakdowns and extend machine lifespan.

Technical Training –

Hands-on operator training for proper usage, basic

troubleshooting, and understanding of test procedures to maximize your machine’s accuracy and productivity.

By combining maintenance and training, we help you maintain reliable testing operations with minimal downtime.

Why Us?

experience spanning over a decade

Serving the industry since 2010

Excellent Google Reviews

Trusted by a many satisfied clients

Experienced Technical Support

A Certified team at you service

High percision testing procedures

Providing results you can rely on

Fully Customised Solutions

Tailored to meet your every need

Commited To Quality Assurance

Our priority is your satisfaction

Our Clients